Fiber Optic Amplifiers: Improving Sensing Precision in Industrial Automation

In the world of today’s industrial automation, fiber optic amplifiers have become essential for tasks that demand speed, flexibility, and durability. These units do more than boost light signals; they deliver fast, precise readings in places where usual sensors can t fit, can t survive, or simply aren t sensitive enough.

This post breaks down how fiber optic amplifiers operate, the main perks they bring to B2B manufacturing, the key areas where they shine, and the must-know points for choosing the right model. It also points to trustworthy suppliers so companies can outfit their lines with sturdy automation gear.

What Are Fiber Optic Amplifiers?

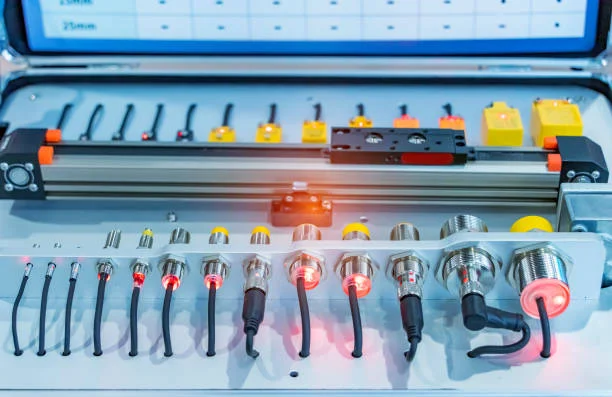

Fiber optic amplifiers are clever little boxes that read and refresh light moving through fiber cables. They pair with fiber optic sensors that use beams instead of wires to spot objects, measure distance, or check surface quality. Because the sensor is usually a small head stuck near the target, all the heavier electronics go inside the amp, turning the faint light into a clean signal the control system can use.

Keeping the sensing head and the amplifier apart comes with several handy benefits:

- Miniaturized sensing heads fit into extremely tight spaces.

- Rugged design lets the sensor head resist heat, chemicals, or even submersion in water.

- Sensitivity and timing can be fine-tuned right at the amplifier.

Because they use lightweight cables, fiber optic amplifiers are popular wherever fast detection, clear-object reading, and flexible installation are essential.

To see practical models and setups, OMCH offers a broad lineup of photoelectric sensors and amplifiers for many automation spaces, including fiber-optic options.

Key Advantages in Industrial Settings

For B2B firms running complex factories, picking the right sensor can boost both output and workplace safety. Fiber optic amplifiers bring a bundle of benefits that let them fit almost any industry.

Miniature Installation Capabilities

Fiber optic heads are tiny enough to fit where standard sensors can’t. They slide into machine interiors, narrow inspection gaps, or dense assembly lines with ease.

High-Speed Detection

Fiber optic sets excel in high-speed sorting, labeling, and positioning jobs. Their light-driven detection cuts response times to the microsecond range, so they shine in tasks where every millisecond counts.

Long Sensing Distance and Flexibility

With coaxial or split-fiber layouts, these amplifiers can spot objects far from the sensor head, especially when paired with powerful emitters and custom lenses.

Harsh Environment Suitability

Because the sensing tip has no built-in electronics, it keeps working in extreme heat, heavy vibration, or places splashed with chemicals or moisture. Only the main amplifier needs a stable room.

Advanced Signal Processing

Most modern fiber-optic amplifiers also offer:

- Automatic gain control

- Dynamic threshold adjustments

- Teach-in settings

- Multi-channel support

These extras let engineers tune the system on the fly for factories where lighting or material reflectivity changes during a run.

Industrial Applications of Fiber Optic Amplifiers

Together, fiber sensors and their amplifiers fill nearly every corner of industrial automation. Here are some of the most popular roles:

Electronics and Semiconductor Manufacturing

In lines where static, heat, and cramped space rule, fiber systems track micro-components, wire paths, or PCB spots. The amplifier makes sure even sub-millimeter parts get detected reliably.

Packaging and Labeling Lines

Many production lines need to tell whether a clear bottle or stretch film is actually there. By running fiber optic cables next to carefully tuned amplifiers, factories can spot those items reliably instead of risking the false signals common with ultrasonic or capacitive sensors.

Precision Part Detection in Robotics

When robotic arms pick-and-place tiny parts, they must know exactly where each piece is. Fiber optic sensors meet that need, sending back position information so fast the motion control system never hesitates.

Food and Beverage Automation

Fiber sensors packed inside stainless steel or Teflon housings count bottles, check caps, and measure liquid levels even in wet, harsh areas. Because the sensing tip resists chemicals, regular cleaning does not knock the system out of calibration.

Automotive Component Assembly

On the automotive line, fiber optic networks watch for proper fit, aligned edges, and even tiny gaps in spots where heat and movement collide. Keeping those checks on every component helps speed assembly while reducing costly rework.

How to Pick the Right Fiber Optic Amplifier

Choosing a fiber optic amplifier isn’t just about picking the first model on the shelf. Because every environment is unique, pay attention to these key details before making a decision.

Sensing Mode and Fiber Type

Start by figuring out the sensing mode you need: through-beam, diffuse-reflective, or retro-reflective. Each style has its own reach, signal power, and how well it stays lined up over distance.

Beam Characteristics and Spot Size

For tasks like edge detection, a tiny spot locks onto the target; for poorly shaped parts, a big beam sweeps the area. In the end, both the fiber cable and the amplifier shape the final spot size.

Mounting and Interface Options

Think about how you’ll hold the amplifier: on a DIN rail, off the side, or flat to the panel. User controls also vary, from simple teach buttons to bright displays linked by IO-Link or RS-485.

Light Source and Wavelength

Red or infrared LED sources work for most jobs, while special builds shine UV or blue light to spot low-contrast items.

Environmental Ratings

Finally, if your amplifier will sit in a hot, dusty, or watery zone, double-check its IP code and temperature range before you buy.

OMCH makes tough, easy-to-use photoelectric amplifier systems that perform well in busy factories and warehouses. Each unit comes with a clear data sheet, so engineers and buyers can quickly see which model fits their machine or line.

Read Also: Top Platforms to Discover Profitable Internet Businesses for Sale

OMCH: Supporting Modern Automation with Sensor Expertise

For companies that need sensors they can count on, OMCH keeps a steady stock of optical sensors, amplifiers, and related parts that meet today’s industrial rules. Backed by years on the shop floor and a full-time R & D team, the brand serves OEMs, systems builders, and plant operators with gear that adapts quickly and works hard.

Whether the task is spotting a clear bottle on a conveyor or checking a tiny circuit board, OMCH technology has earned praise for lightning-fast response, sharp signal quality, and installation options that save time and space.

To explore fiber-optic-ready models or classic photoelectric heads, jump over to the https://www.omchsmps.com/ru/path/photoelectric-sensor/, where every solution is labeled for easy matching to precision jobs in any sector.

Conclusion

In tight, hostile spots, fiber-optic amplifiers give factories the speed and accuracy they crave, turning weak signals into clear detections almost instantly. Because the modules snap together, run cool, and adapt to different cables and lenses, they fit perfectly in modern automation setups that demand both power and peace of mind.

More companies are looking for smart sensors that work anywhere, so adding tough, expandable fiber-optic gear can give B2B firms a real edge. Reputable partners like OMCH have the parts and know-how to make sensor set-ups easy and keep them running strong for years.