How Aluminum CNC Parts Improve Heat Dissipation in High-Power Electronics

High-power gadgets, from cloud servers to electric cars and factory robots, demand smart ways to keep heat in check. If excess heat isn’t moved away quickly, even cutting-edge gear can shut down, fail, or wear out far too soon. Aluminum CNC parts made by low-cost Chinese precision shops help solve the problem thanks to their fast heat spread, tight fit, and design freedom.

This post shows how these machined aluminum pieces are reshaping cooling systems for B2B electronics builders.

Why Heat Dissipation Matters in High-Power Gear

As chips shrink, pack more transistors, and work harder, the heat they generate keeps rising, and keeping that heat under control is now a major engineering test. When thermal management falls short, a device can suffer:

- Sluggish performance and lost data signals

- Shorter life for processors, boards, and batteries

- Dangerous thermal runaway in high-voltage circuits

- Bigger maintenance bills for users

Engineers fight those problems by using metals that pull heat away fast yet hold their shape. Aluminum, with its excellent thermal conductivity and light weight, has become the go-to choice.

Why Aluminum Is Best for Managing Heat

Everyone in the electronics world knows aluminum dissipates heat fast. With a thermal conductivity around 235 W/m·K, the metal quickly pours excess warmth away from sensitive chips and circuits. Yet that property by itself will not guarantee good performance. Parts must also fit together within a few microns of space, or hot spots appear.

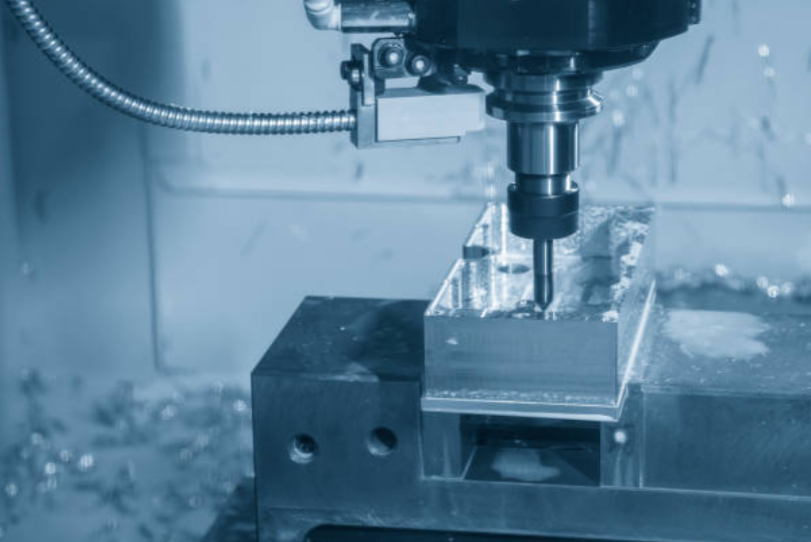

That is why many designers turn to China CNC precision machining. Modern computer-controlled mills and lathes cut, drill, and shape aluminum to the exact dimensions every assembly demands, sealing flawless contact points and smooth paths for heat to travel.

Key Reasons Designers Pick Aluminum for Heat Dissipation

- High Thermal Conductivity: Quickly carries heat away from hot spots.

- Lightweight: Adds strength without bulky weight.

- Corrosion Resistance: Stands up to humidity and industrial gases.

- Excellent Machinability: Shapes complex parts fast and to tight tolerances.

The Role of CNC Machining in Thermal Component Design

Alloys can shine thermally, but only when paired with the accuracy CNC machining delivers. Techniques such as milling, turning, and EDM let engineers craft fine edges, deep channels, and mirror-like surfaces critical for smooth heat flow. When every surface mates with exactitude, heat moves swiftly across the entire device, prolonging life and reliability.

Key CNC Features That Boost Heat Handling

- Tight Tolerances: When parts fit snugly, thermal contact with the heat source stays uniform.

- Smooth Surface Finish: A mirror-like surface cuts tiny air pockets, letting heat flow freely.

- Complex Geometry Support: CNC tools easily craft fins, vents, and winding channels for air or liquid coolant.

- Modular Production: Quick prototypes and fast runs let engineers tweak designs on the fly.

Because of this speed and flexibility, many design teams work hand-in-hand with their china cnc precision machining shops to shape parts for cooling rather than just strength.

Read Also: Technological Changes Altering Business in 2025

Where CNC-Machined Aluminum Meets High-Power Electronics

Aluminum components made on CNC machines now land in demanding systems where overheating can spell disaster. Key applications include:

Heat Sinks and Spreaders

The most obvious role, machined heat sinks, sport dense fin patterns that stretch surface area sky-high. Exact spacing keeps air or fluid flow even, so heat slides off as quickly as possible.

Power Electronics Enclosures

Aluminum housings soak up heat from inverters, power supplies, and amplifiers, keeping components cool. With CNC machining, makers add thermal ribs, mounting channels, and connector slots in one step- lower thermal resistance and quicker assembly.

Battery Cooling Plates

In electric cars and storage banks, aluminum plates sport winding internal ducts for liquid coolant. Machinists cut these ducts to the tightest tolerances; even a tiny leak could spoil cooling and leave cells uneven.

LED Modules and Optical Systems

Bright LED arrays lose output and life when they overheat. Thin aluminum boards and CNC-finished heat sinks drain excess heat while letting engineers align lenses and reflectors with exacting accuracy.

Telecom and Server Equipment

CNC-cut aluminum baseplates and racks deliver structural strength and fast thermal conductivity at once. In crowded server rooms and comms closets, they keep critical gear inside safe temperature limits.

Across all applications, close teamwork between designers and china cnc precision machining shops turns drawings into parts that work under real-world heat, shock, and vibration.

Picking the Best CNC Shop for Thermal Parts

Not every machine shop handles heat-friendly aluminum the same way. When thermal management is the main goal, you need a supplier with a track record in lightweight metal work and tight tolerances.

Key Traits to Check:

- Know-How with Heat Flow: The team should grasp how pocket shape, wall angle, and surface finish move warmth through the part.

- Advanced Machining Gear: Look for shops that run multi-axis mills, EDM, or micro-cutters so you can design without extra worry.

- Aluminum Savvy: They should understand 6061, 7075, 1050 and how each alloy balances conductivity against strength.

- Steel-Grade Quality Checks: Small burrs or off-sizes can kill thermal transfer, so incoming, in-process, and final inspections matter.

- Fast Prototype Turnaround: Quick samples let you test and tweak before the production line starts, crucial in speedy electronics fields.

Partnering with a solid China CNC precision machining shop gives you sharp craft and good prices, whether you are moving from a single test run to a thousand parts.

Future Trends: Smart Thermal Systems and Design Tweaks

As new cooling problems crop up, CNC-cut aluminum parts are set to headline future gadget builds. Watch for these moves:

- Built-In Liquid Cooling: Skilled machining lets makers carve hidden channels so self-contained coolant loops fit tight spaces.

- Topology Tuning: Design-O-Matic brain apps create wild shapes that machines can mill, dumping heat fast while shedding excess weight.

- Mixed-Material Assets: Makers bond aluminum with ceramic or plastic bits to tailor heat and current paths for each job.

- Green Fab: Easy to recycle and low on power, aluminum meets the growing shout for planet-friendly electronics.

Companies that want to lead tomorrow should line up their drawings and suppliers with these CNC-friendly ideas now.

Conclusion: Gaining the Edge with Precision Cooling

In the world of muscle electronics, aluminum CNC parts do more than sit inside-they cool, stabilize, and prolong gear life. Their knack for pulling heat from hot spots gets a power boost from today’s exact, flexible machining.

Partnering with a skilled China CNC precision machining shop helps B2B companies turn good thermal ideas into designs that work and grow. Whether you are making battery packs, rugged industrial PCs, or next-gen power converters, every solid aluminum solution starts with a clear plan and finishes with a CNC-machined part that stands up to real stress.